In early 2022, Routsis Training launched a unique, reliable, and cost-effective tool for workforce training and benchmarking — based on their popular Professional Certification Programs for plastics processing.

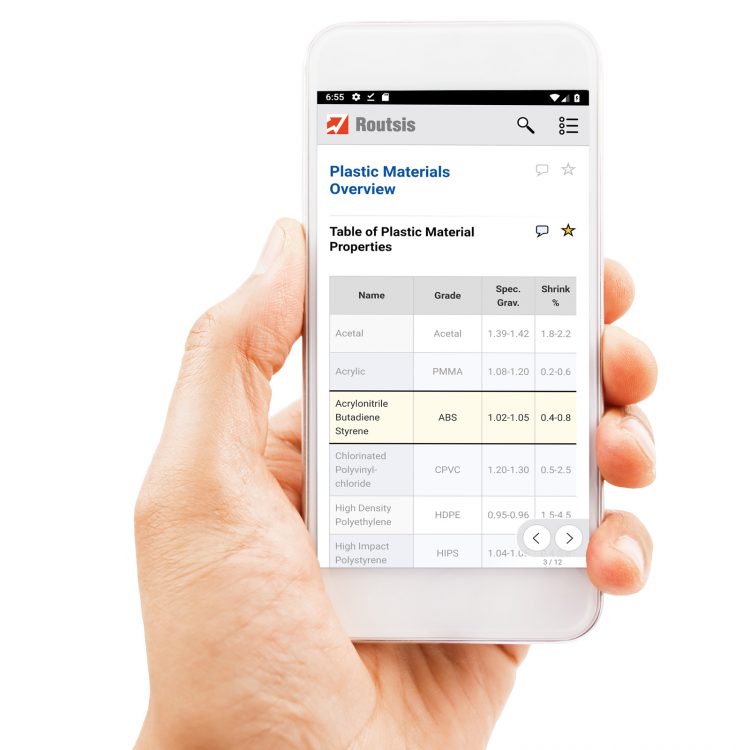

These Professional Certification Training Portals — or “Cert Portals,” as they’re commonly called — combine over 25 hours of powerful online training with a certification exam that evaluates the candidate’s understanding of important concepts that directly relate to their jobs.

“It’s an extremely cost-effective way to train your entire workforce. And these portals can be set-up very quickly, which allows companies to start seeing benefits almost immediately.”

Daniel Stephens, Vice President of Routsis Training

“The Cert Portals are becoming the go-to solution for on-boarding and employee development: particularly for small to mid-sized molders, extruders, and design firms,” stated Daniel Stephens, Vice President of Routsis Training. “It’s an extremely cost-effective way to train your entire workforce. And these portals can be set-up very quickly, which allows companies to start seeing benefits almost immediately,” Mr. Stephens said.

Routsis offers two different levels of Professional Certification for Injection Molding. There are also certification programs for Injection Mold & Plastic Part Design, Single-Screw and Twin-Screw Extrusion, and Extrusion Blow Molding. “If your plant runs multiple processes, we can easily create a custom solution that meets your facility’s particular needs,” said Mr. Stephens.

By default, each Cert Portal is configured to run two separate training tracks, geared toward different job positions and skill requirements:

- Fundamental Courses

This “101” course grouping benefits anyone in the facility by establishing a consistent knowledgebase, while emphasizing all aspects of safety. - Professional Certification

These courses cover process parameters, lean manufacturing, troubleshooting, and other topics; benefitting Technicians, Supervisors, Managers, and Engineers.

Routsis Training will help you determine the number of active seats your plant needs. Once an employee has completed their assigned training, employers can use that seat to train another employee, according to Stephen Murphy, President of Routsis Training.

“Certification sharpens a company’s competitive edge and shows their customers that they’re committed to continuous quality improvement,” Mr. Murphy added.