Does your company give lip-service to cleanliness and organization or does it take it seriously every day? In this post, we’ll take a look at ways in which tidiness can save your company time and money, and increase the safety of your workplace.

Merriam-Webster defines cleanliness as ‘the quality or state of being clean.’ A clean workplace is one in which normal operations can take place without concerns of contamination or injury resulting from the current state of cleanliness.

The expectations at each production facility are a little different, but the common expectations are as follows: clean floors, clean surfaces, and clean equipment. In practice, this means no oils, liquids, pellets, dust, or clutter anywhere on the production floor.

Clean Floors

All floors must be kept clean regularly with scheduled sweeping and mopping. Sweeping the floor is good, but mopping is one of the most effective ways to reduce the overall amount of dust and airborne particulates on the production floor. Never use air hoses to clean the floors, as they generate a large amount of airborne particulates that eventually become contaminate surfaces, internal components, and plastic materials.

Clean Surfaces

Every visible and accessible machine surface should be cleaned thoroughly. There must be a schedule and procedure for cleaning everything on your production floor: from wiping the tables to cleaning the protective guards on your machinery. When potential customers visit your plant, they check for dust in non-obvious areas, such as the top of your machine guards or behind an inspection table.

Clean Equipment

The equipment on the production floor needs to be in good working condition and look that way. Rusty molds, damaged robots, and red-tagged thermolators should not be commonplace in your production environment. The production floor is for things which are to be used for production.

Broken or faulty equipment is effectively clutter if it is just sitting around on the production floor. Keep in mind that your customers usually won’t tell you the place is dusty or cluttered — they will just start moving their jobs somewhere else.

Organization

Organization is not a static state, but a continuous process: The goal should always be continuous improvement. There are multiple levels of organization, the first is to determine what things below, second is to have that place for things, and third is to always look for better places to keep things.

Everything on the production floor should have immediate purpose. Organization starts with only having what you need on the production floor. Everything that does not belong is either thrown away or stored somewhere else.

Next, each important item that remains on your production floor should have its own convenient, specifically-designated place. ‘A place for everything and everything in its place’ has additional meaning when applied to a production environment.

The most important part of continuous improvement is to find better ways to do things. This includes better ways to store and access things on the production floor. You may keep tools like brass rods and wire brushes in a box near the machine — and this may be helpful and convenient — but a shadow-board on the machine where items can be accessed immediately might be even better.

Always keep an eye out for better ways to clean and organize the production floor: improving accessibility, using the available area more efficiently, and reducing the chance that conditions will degrade.

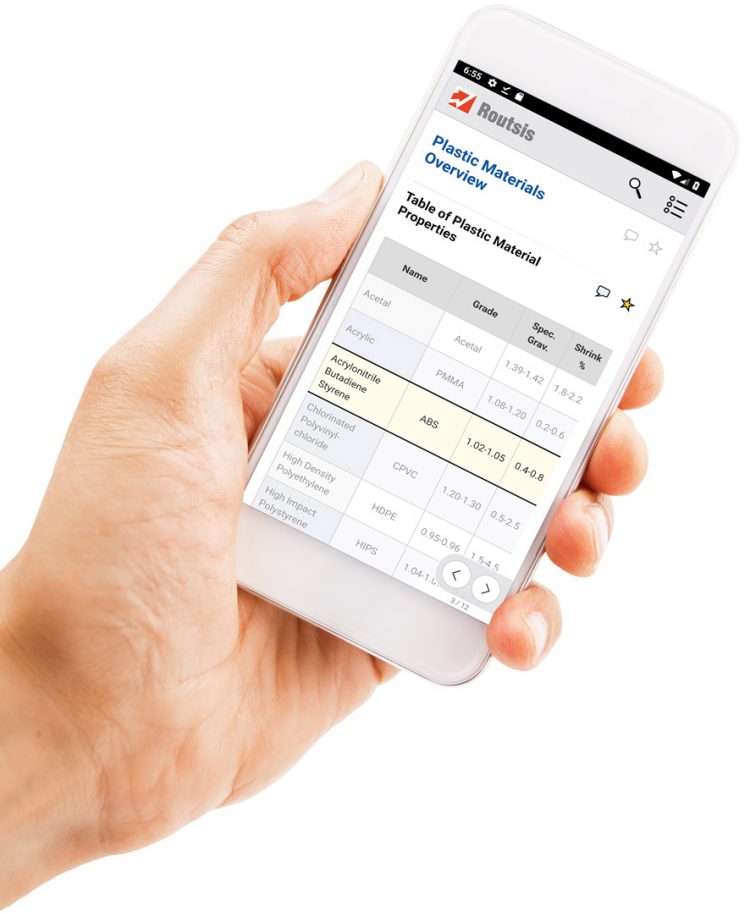

These concepts are part of the 5S lean manufacturing methodology. Routsis Training has developed an excellent training series, The 5S System. Based on our exclusive SkillSet™ learning model, these innovative labs combine online training with hands-on worksheets.