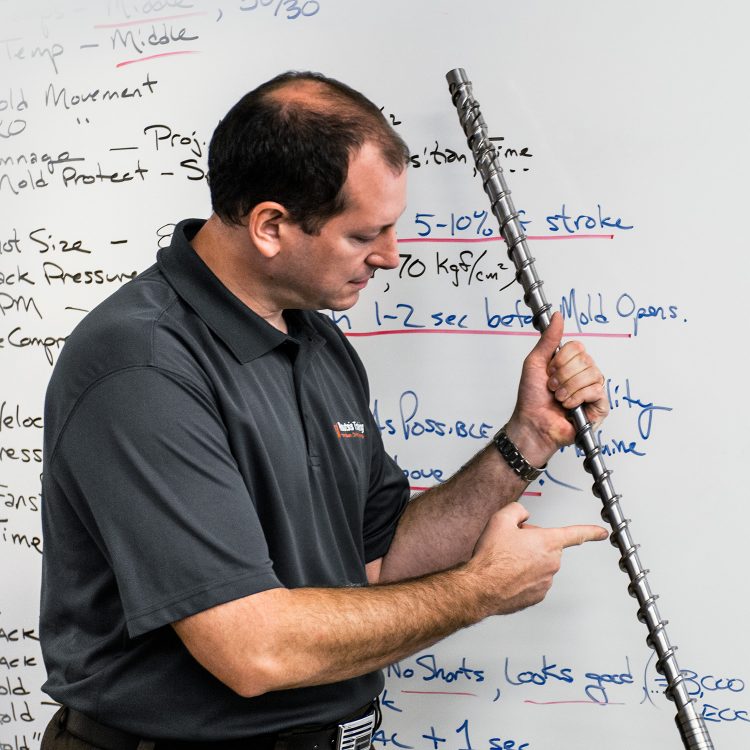

Not to toot our own horn here… but we are extremely proud of our RightStart™ system. It truly has no equal in the plastics industry. RightStart™ was developed by leading industry experts and is used by many top-performing plastics manufacturers worldwide. In fact, it is more than just a training system: It’s a solution to […]