Did you know there are 4 different types of material dryers commonly used in the plastics industry? In fact, many processing facilities are using the wrong type of dryer for their material drying application. In this post, we will discuss each type of dryer and its appropriate usage.

Hot Air Dryers

The most basic type of dryer is a hot air dryer. These typically consist of a blower, filter, heater, and temperature controller. Such dryers are great with non-hygroscopic materials where removing surface moisture is needed or the material needs to be pre-heated for high-speed processing.

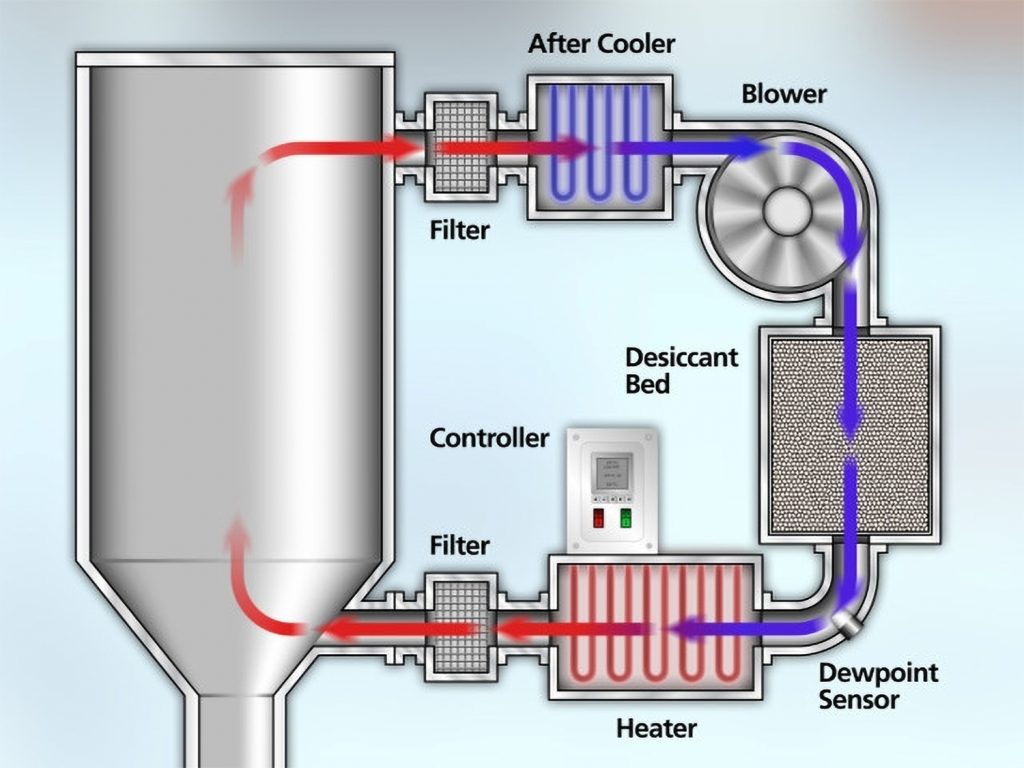

Desiccant Dryers

The most common dryer used in the industry is the desiccant dryer because they bring the dewpoint of the air down to -40°C (-40°F). These typically consist of an aftercooler, blower, desiccant bed, dewpoint sensor, heater, filter, temperature controller, and regeneration system. These are great at drying hygroscopic materials, but are very complex pieces of machinery which require a lot of maintenance to keep running.

Compressed Air Dryers

A simpler type of hygroscopic material dryer is the compressed air dryer. These are almost identical to a hot air dryer except they get their inlet air from your compressed air supply. If you air system is properly maintained, the compressed air dryer provides air as dry as negative 20 degrees Celsius. These systems are becoming very popular as hopper dryers for drying small amounts of materials as well as hygroscopic materials warm and dry in high-speed applications.

Vacuum Dryers

Vacuum dryers are the fastest, most efficient systems available for batch-drying hygroscopic materials. These systems heat the pellets in a canister and then draw a vacuum to quickly remove the moisture from the material. These systems are complex and expensive, but can dry a batch of material as quickly as 30 minutes! Desiccant dryers are the most commonly used systems in the plastics industry, but they are not always the best choice.

For more information about moisture measurement and material drying, be sure to check out Routsis Training’s Material Drying Technology. This online training programs give personnel a better understanding of how different polymers are best dried and prepared for reliable processing — and demonstrate how proper plastics material handling is critical to developing a consistent process and delivering quality products to your customers.

0 Comments Leave a comment